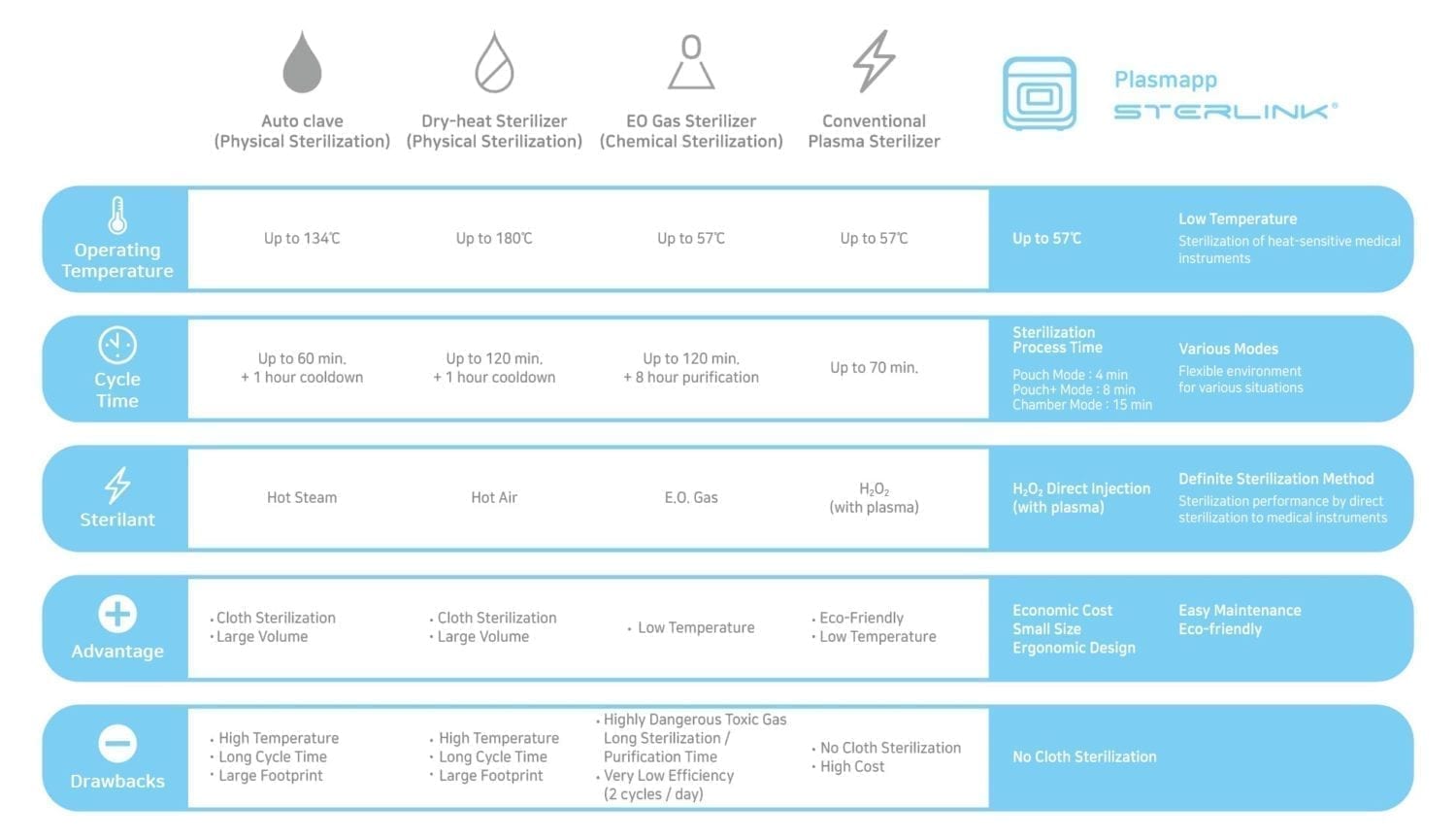

We are proud to represent Plasmapp which has developed STERLINK®. This system is the first compact, efficient and cost effective low temperature sterilizer on the market. It offers a safe and non-toxic sterilization process utilizing hydrogen peroxide in a fraction of the processing time of an ethylene oxide sterilizer. Sterilization can be done in 7 to 36 minutes versus 12 hours!

VETOVATION HAS BEEN NAMED THE U.S. DISTRIBUTER FOR PLASMAPP

VETOVATION HAS BEEN NAMED THE US DISTRIBUTER FOR PLASMAPP

Introducing On-Demand Gas Plasma Sterilization for Veterinary Hospitals

We are proud to represent Plasmapp which has developed STERLINK®. This system is the first compact, efficient and cost effective low temperature sterilizer on the market. It offers a safe and non-toxic sterilization process utilizing hydrogen peroxide in a fraction of the processing time of an ethylene oxide sterilizer. Sterilization can be done in 7 to 36 minutes versus 12 hours!

IN USE SINCE 1993

History of Gas Plasma Sterilization

One of the principal benefits of gas plasma sterilization as compared to Ethylene Oxide (EtO) is that it provides the required heat level (<140° F) for sensitive surgical instruments with none of the off-gassing concerns of EtO.

Gas plasma sterilization was originally used by large manufacturers of medical devices to sterilize human-use disposable items.

Johnson and Johnson first marketed gas plasma to hospitals in the US in 1993, under the ASP brand. Historically, gas plasma options have been expensive and very large. It is for this reason that it has been inaccessible to veterinary clinics around the world despite being non-toxic and the best alternative to EtO sterilization.

However, in 2014 the STERLINK® system was developed through the combination of medical gas plasma sterilization and vaporizer vacuum technology.

Now, this technology is available for use in veterinary clinics around the world as a superior alternative to traditional Ethylene Oxide (EtO) sterilization.

3 USAGE MODES

Explore Each of the Modes Available

36 MINUTE

Chamber Mode

Single use recyclable gas plasma sterilant cartridges power the 14-liter chamber for the processing of multiple packages at once

14 MINUTE

Pouch Mode

Direct injection gas plasma sterilization under a smaller volume vacuum reduces gas plasma cycle time and improves sterilant penetration

7 MINUTE

Pouch Mode

Cycle times are further reduced for increased flexibility and just-in-time availability of instruments. Safe, fast, and effective.

IN USE SINCE 1993

History of Gas Plasma Sterilization

One of the principal benefits of gas plasma sterilization as compared to Ethylene Oxide (EtO) is that it provides the required heat level (<140° F) for sensitive surgical instruments with none of the off-gassing concerns of EtO.

Gas plasma sterilization was originally used by large manufacturers of medical devices to sterilize human-use disposable items.

Johnson and Johnson first marketed gas plasma to hospitals in the US in 1993, under the ASP brand. Historically, gas plasma options have been expensive and very large. It is for this reason that it has been inaccessible to veterinary clinics around the world despite being non-toxic and the best alternative to EtO sterilization.

However, in 2014 the STERLINK® system was developed through the combination of medical gas plasma sterilization and vaporizer vacuum technology.

Now, this technology is available for use in veterinary clinics around the world as a superior alternative to traditional Ethylene Oxide (EtO) sterilization.

3 USAGE MODES

Explore Each of the Modes Available

36 MINUTE

Chamber Mode

Single use recyclable gas plasma sterilant cartridges power the 14-liter chamber for the processing of multiple packages at once

14 MINUTE

Pouch Mode

Direct injection gas plasma sterilization under a smaller volume vacuum reduces gas plasma cycle time and improves sterilant penetration

7 MINUTE

Pouch Mode

Cycle times are further reduced for increased flexibility and just-in-time availability of instruments. Safe, fast, and effective.

Frequently Asked Questions

Answers to the Most Common Questions

For surgical instruments that are moisture or heat sensitive (not suitable for steam autoclaves), low temperature sterilization is a requirement. A leading option for low temperature sterilization is hydrogen peroxide gas plasma. This technique is widely available in large hospitals in the US. Plasmapp brings this process to the STERLINK® suite.

In the past smaller practices, due to limitations on space and prohibitive costs, have relied primarily on hand sterilization or the use of inefficient and toxic methods of sterilization like Ethylene Oxide (EtO) or Ozone. EtO is not only toxic; it can also take up to 12 hours to completely reprocess instruments utilizing this sterilization method.

This inefficiency puts unnecessary strain on modern practices both in terms of workflow flexibility and infection control, as well as profitability.

For more information, contact our team to learn more about the benefits of gas plasma sterilization and the STERLINK® suite.

Gas Plasma sterilization with the STERLINK® system is intended for items that are not suitable for high temperature steam. Many instruments used by veterinary clinics today are very sensitive to heat and moisture. This requires flexibility in small practices. Consult the Sterility Guide published by ASP which contains manufacturer specific certifications for thousands of instruments; below are the major categories compatible with STERLINK®.

| Batteries | Cranial Pressure Transducer Cables | Cryoprobes |

| Defibrillator Paddles | Resectoscopes and working elements | Dopplers |

| Rigid and flexible scopes/endoscopes | Electrocautery instruments | Shaver handpieces |

| Endoscopic instruments | Single-channel flexible endoscopes | Esophegeal dilators |

| Stereotactic equipment | Fiberoptic light cables | Surgical Drills |

| Laryngoscopes and blades | Thermometers | Laser handpieces, probes, fibers, and accessories |

| Trocar sheaths | Metal instruments | Ultrasound probes |

| Ophthalmic lenses | Video cameras and couplers | and more |

Please contact us directly for more information and to answer questions about the STERLINK® system.

When in Chamber mode the entire volume of the STERLINK® is usable. However, take care not to cover the vacuum port on the unit. Unlike steam autoclaves, no space is required in between packaging.

When in STERPACK mode, the volume is limited to the pack dimensions. These packs are most frequently used for on-demand requirements and single instruments.

No, trays are not required when using STERPACKs. However, it is important to consider if the instrument in the pouch is sharp or fragile. Without protection from the vacuum protection of the pouch, sharper items may puncture the pouch or fragile instruments may sustain damage.

Frequently Asked Questions

Answers to the Most Common Questions

For surgical instruments that are moisture or heat sensitive (not suitable for steam autoclaves), low temperature sterilization is a requirement. A leading option for low temperature sterilization is hydrogen peroxide gas plasma. This technique is widely available in large hospitals in the US. Plasmapp brings this process to the STERLINK® suite.

In the past smaller practices, due to limitations on space and prohibitive costs, have relied primarily on hand sterilization or the use of inefficient and toxic methods of sterilization like Ethylene Oxide (EtO) or Ozone. EtO is not only toxic; it can also take up to 12 hours to completely reprocess instruments utilizing this sterilization method.

This inefficiency puts unnecessary strain on modern practices both in terms of workflow flexibility and infection control, as well as profitability.

For more information, contact our team to learn more about the benefits of gas plasma sterilization and the STERLINK® suite.

Gas Plasma sterilization with the STERLINK® system is intended for items that are not suitable for high temperature steam. Many instruments used by veterinary clinics today are very sensitive to heat and moisture. This requires flexibility in small practices. Consult the Sterility Guide published by ASP which contains manufacturer specific certifications for thousands of instruments; below are the major categories compatible with STERLINK®.

| Batteries | Cranial Pressure Transducer Cables | Cryoprobes |

| Defibrillator Paddles | Resectoscopes and working elements | Dopplers |

| Rigid and flexible scopes/endoscopes | Electrocautery instruments | Shaver handpieces |

| Endoscopic instruments | Single-channel flexible endoscopes | Esophegeal dilators |

| Stereotactic equipment | Fiberoptic light cables | Surgical Drills |

| Laryngoscopes and blades | Thermometers | Laser handpieces, probes, fibers, and accessories |

| Trocar sheaths | Metal instruments | Ultrasound probes |

| Ophthalmic lenses | Video cameras and couplers | and more |

Please contact us directly for more information and to answer questions about the STERLINK® system.

When in Chamber mode the entire volume of the STERLINK® is usable. However, take care not to cover the vacuum port on the unit. Unlike steam autoclaves, no space is required in between packaging.

When in STERPACK mode, the volume is limited to the pack dimensions. These packs are most frequently used for on-demand requirements and single instruments.

No, trays are not required when using STERPACKs. However, it is important to consider if the instrument in the pouch is sharp or fragile. Without protection from the vacuum protection of the pouch, sharper items may puncture the pouch or fragile instruments may sustain damage.