Hydrogen Peroxide Plasma Sterilization

Many busy veterinary hospitals are discovering that hydrogen peroxide plasma sterilization offers a fast, safe alternative to EtO gas and steam provides a fast, safe alternative to EtO (ethylene oxide) gas and steam sterilization. For veterinary hospitals trying to turn cases quickly and reuse many traditionally disposable surgical items. Hydrogen peroxide (H202) plasma sterilization has become an affordable alternative to traditional sterilization modalities.

For years, EtO sterilization was the only alternative to steam sterilization. Autoclaves are reliable, familiar, and for most clinics, the only real option. But as veterinary surgery evolves, many practices are starting to ask a new question:

Is there a better way to sterilize instruments safely, efficiently, and sustainably?

The Challenge: Time, Temperature, and Turnover

Surgical schedules are tighter than ever. From routine spays to complex orthopedic procedures, clinics rely on instrument sets being ready now, not an hour from now.

Autoclaves get the job done, but the process has limitations. The combination of high heat, steam, and long drying cycles can slow down the day. And for clinics that use LigaSure vessel sealers, cameras, or other delicate tools, those same conditions can shorten the lifespan of expensive equipment.

As one technician put it:

“It’s not that autoclaves don’t work, it’s that they slow us down.”

That frustration has led many teams to explore low-temperature sterilization, and one method in particular is getting attention: gas plasma sterilization.

What Is Gas Plasma Sterilization?

Gas plasma sterilization uses vaporized hydrogen peroxide that’s energized into a plasma state. It effectively destroys microorganisms at the molecular level, without heat, moisture, or chemical residue.

To the average vet tech, that means fewer steps, less waiting, and no worries about moisture-sensitive devices. The process is also environmentally friendly, with no risk handling hazardous materials or chemical disposal, no external venting.Cycle times are measured in minutes, not hours. That difference alone can help clinics complete more procedures in a day, with less stress on the team.

EtO vs. Hydrogen Peroxide Plasma Sterilization: What’s the Difference?

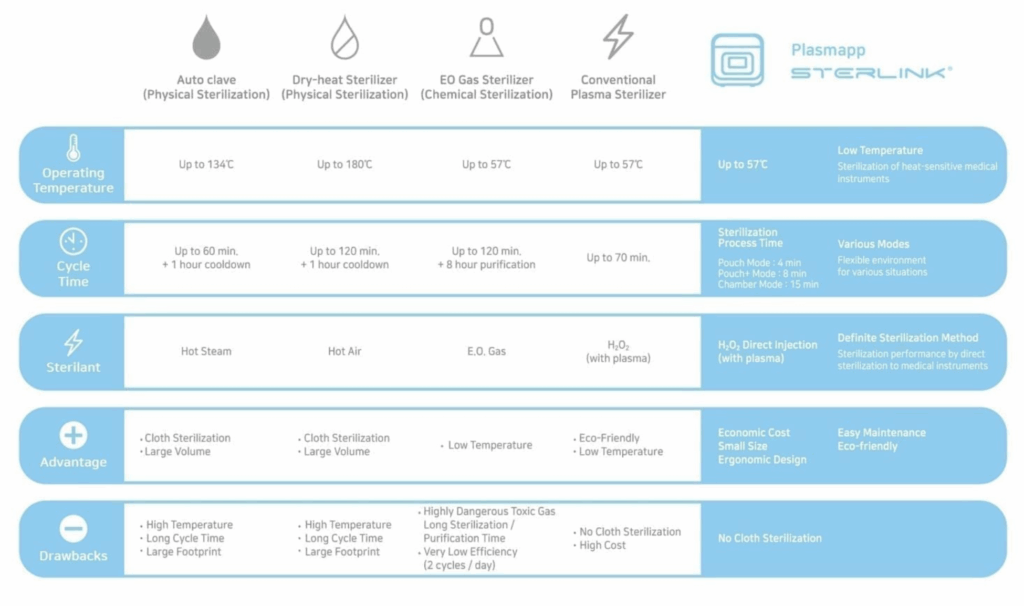

Both EtO and hydrogen peroxide plasma sterilization are designed for instruments that cannot withstand heat or moisture. But they differ in safety, speed, and environmental impact.

EtO remains effective but increasingly difficult to manage in small or midsize veterinary practices. The regulatory and safety burden alone makes it impractical for many modern clinics.

For most veterinary instruments, particularly vessel sealer handles, electrosurgery handpieces, and delicate cameras and scope, hydrogen peroxide plasma offers the right mix of safety, speed, and reliability.

A Real-World Example: Streamlining the Surgical Day

One small-animal hospital we worked with recently adopted hydrogen peroxide plasma sterilization to keep up with increasing caseloads. Within a week:

-

- Turnaround time dropped from 45 minutes to under 20

-

- Vessel sealer handles and delicate scopes could now be sterilized between cases.

-

- The surgical schedule became smoother, with fewer frustrations for the doctors and staff.

As their lead technician put it:

“It’s like removing a speed bump from the middle of the day.

Inside the Sterlink U-510: Gas Plasma Sterilizer

The Sterlink U-510 Gas Plasma Sterilizer brings this same technology into a compact, plug-and-play system built for veterinary use.

Key features:

-

- Low-temperature hydrogen peroxide plasma sterilization

-

- Sterilization cycle times as quick as 17 or 24 minutes

-

- Items are warm to the touch following the sterilization cycle

-

- Touchscreen interface and preloaded cassettes, no manual chemical handling

-

- Compact size that fits seamlessly in most treatment areas

-

- Instruments are warm to the touch and ready for surgery

It’s a practical solution for clinics that want shorter cycles, safer workflows, and longer-lasting instruments.

Protecting Your Most Valuable Tools: Why Sterilization and Vessel Sealers Go Hand-in-Hand

As more veterinary hospitals look for faster, safer sterilization methods, many are also upgrading the surgical instruments they rely on every day, especially vessel sealers. These devices have become essential in both general and specialty surgery thanks to their ability to reduce bleeding, shorten procedure times, and improve patient recovery.

However, vessel sealer handles, cables, and electrosurgery accessories are also some of the most sensitive instruments in the OR, making your sterilization choice even more important. High heat and moisture from traditional autoclaves can shorten component lifespan or slow down surgical turnover. That’s one reason many clinics transitioning to hydrogen peroxide plasma sterilization are also seeing improved performance and longevity from their vessel sealers.

If your team is evaluating ways to streamline surgery, upgrade instrumentation, or improve outcomes, pairing modern vessel sealing technology with a low-temperature sterilization workflow can make a significant impact on efficiency and patient safety.

👉 Learn how vessel sealers are transforming veterinary surgery and why more hospitals are adopting them. Read our guide on Why Vessel Sealers Are Revolutionizing Veterinary Surgery Outcomes.

Why This Shift Matters

The evolution of sterilization reflects a broader trend in veterinary medicine: balancing performance with safety, sustainability and affordability.

EtO was once the go-to for sensitive instruments, but its risks and regulatory hurdles make it less viable today. Hydrogen peroxide plasma offers a future-ready alternative, one that supports staff health, environmental goals, and operational efficiency.

For veterinary hospitals constantly balancing patient care and wanting to keep the cost of surgery affordable for the client this progress matters. Enabling hospitals to be able to safely reuse traditional single patient use items from the human hospital saves money for the hospital and client.

Learn More

If your clinic is evaluating alternatives to steam or EtO sterilization, explore how the Sterlink U-510 Gas Plasma Sterilizer Starter Kit can simplify your workflow and help your team do more, safely.

Contact us below to learn more.